Bugle Head Black Phosphate/Galvanized Drywall Screw

What is dry wall screws?

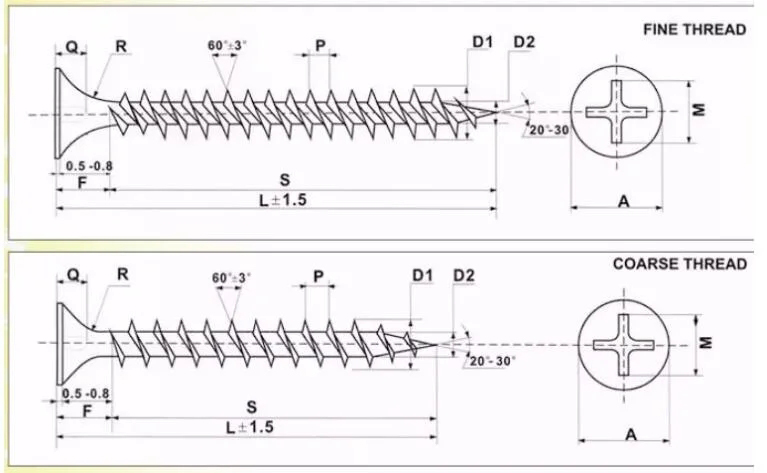

Drywall screws, or sheetrock screws, are specialized self-tapping screws that usually feature a bugle head that is designed to attach drywall to studs, and a phosphate finish. In the construction industry, sheetrock screws have many alternative uses because they are relatively inexpensive, feature a flat head that is less prone to getting pulled through the wood, and thin, making these self tapping sheetrock screws less likely to split the wood. They are available with a coarse thread, fine thread, high-low pattern thread, and sometimes feature a trim head rather than a bugle head.

Size

Types of drywall screws

Coarse Thread Drywall Screws

Screws with a bugle head, spaced threads, an extra sharp point, and a black phosphate finish. They are similar in design to particle board screws, however those are available in shorter lengths. They are good for attaching drywall to wood studs or to 25 gage metal studs.

Fine Thread Drywall Screws

Screws with a bugle head, twinfast thread, extra sharp or self-drilling point, and black phosphate finish. The sharp point style is used for attaching drywall to metal studs from 25 gage through 20 gage thick, whereas the drill point will drive easily though drywall, drill a hole in a steel stud up to 14 gage thick, and form its own mating thread. The drill point drywall screw can also be used for attaching plywood or insulation board to 14 gage metal.

High-Low Drywall Screws

Bugle head self-tapping screws with a double-lead, consisting of a high and low thread, and an extra sharp point. They frequently are supplied with a phosphate finish. The high-low drywall screw requires less torque to drive compared to a standard twinfast drywall screw, and commonly used for attaching drywall to light metal or wood applications. The high-low thread design is more resistant to vibration and therefore reduces the chance of heads popping.

Trim Head Drywall Screws

Self-tapping screws that have a twinfast thread, extra sharp point, and countersunk flat head of a width with 1/3 less than a standard drywall screw. They are most frequently used for attaching wood framing of up to 20 gage thick. Trim head drywall screws are offered with a phillips drive or square drive, though the square drive style is preferred when greater torque is needed during installation. It is important to note that there is no single standard for trim head drywall screw dimensions. Dimensions may vary between brands.

Applications

Drywall screws are used to attach wallboard to studs. But the toothy threads and trumpet-shaped heads make them a tempting choice for other tasks. Here are some other smart ways to put them to use.

▲Put up a Paint Station

This Old House master carpenter Norm Abram screws one drywall screw through each corner of a scrap board and rests cabinet doors he’s just painted on the four points for a makeshift drying rack.

▲Replace a Punch

If you’re trying to drill a hole in a tile, but the drill bit keeps “walking”, This Old House general contractor Tom Silva gently taps a 2-inch drywall screw with a hammer to create a chip. This keeps the drill bit in place and helps masonry bits get started.

▲Snake a Sink

With threads so toothy they snag on fibers, a drywall screw tied to a string and twirled in a drain can clear a mild hair clog.

▲Craft a Trammel

Tom Silva fashions his from the points of two screws driven through a strip of wood. By spacing them as wide as his proposed radius, he can scratch a perfect arc or circle.

▲Pilot a Hole

10 uses, drill, pre-drill, drywall screw

In lieu of a 1⁄8-inch starter bit, a drywall screw will pre-drill an easy path for larger hand-turned hooks, eye screws, and lag bolts in a pinch.

▲Silence a Squeak

For creaking floors beneath the carpet, find where the floor meets a joist, then put a 2-inch drywall screw an inch and a half into it through the carpet. A sharp, glancing blow with a hammer will snap off the head safely below the carpet’s pile.

▲Substitute For a Stopper

Twist a drywall screw into the nozzle of a tube of glue or caulk to clear and seal it; leave it in for a top that screws off.

Drywall Screw

| Material | Carbon steel 1022 hardened or stainless steel |

| Size | All size,M3.5X13-M4.8X200 / 6#x5/8~ 14#X3'' |

| Surface | Black/Grey Phosphate or Zinc Plated , Nick Plated |

| Point | Drill point or sharp point |

| Thread | fine thread, coarse thread |

| Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) |

| 3.5*13 | #6*1/2 | 3.5*65 | #6*2-1/2 | 4.2*13 | #8*1/2 | 4.2*102 | #8*4 |

| 3.5*16 | #6*5/8 | 3.5*75 | #6*3 | 4.2*16 | #8*5/8 | 4.8*51 | #10*2 |

| 3.5*19 | #6*3/4 | 3.9*20 | #7*3/4 | 4.2*19 | #8*3/4 | 4.8*65 | #10*2-1/2 |

| 3.5*25 | #6*1 | 3.9*25 | #7*1 | 4.2*25 | #8*1 | 4.8*70 | #10*2-3/4 |

| 3.5*29 | #6*1-1/8 | 3.9*30 | #7*1-1/8 | 4.2*32 | #8*1-1/4 | 4.8*75 | #10*3 |

| 3.5*32 | #6*1-1/4 | 3.9*32 | #7*1-1/4 | 4.2*34 | #8*1-1/2 | 4.8*90 | #10*3-1/2 |

| 3.5*35 | #6*1-3/8 | 3.9*35 | #7*1-1/2 | 4.2*38 | #8*1-5/8 | 4.8*100 | #10*4 |

| 3.5*38 | #6*1-1/2 | 3.9*38 | #7*1-5/8 | 4.2*40 | #8*1-3/4 | 4.8*115 | #10*4-1/2 |

| 3.5*41 | #6*1-5/8 | 3.9*40 | #7*1-3/4 | 4.2*51 | #8*2 | 4.8*120 | #10*4-3/4 |

| 3.5*45 | #6*1-3/4 | 3.9*45 | #7*1-7/8 | 4.2*65 | #8*2-1/2 | 4.8*125 | #10*5 |

| 3.5*51 | #6*2 | 3.9*51 | #7*2 | 4.2*70 | #8*2-3/4 | 4.8*127 | #10*5-1/8 |

| 3.5*55 | #6*2-1/8 | 3.9*55 | #7*2-1/8 | 4.2*75 | #8*3 | 4.8*150 | #10*6 |

| 3.5*57 | #6*2-1/4 | 3.9*65 | #7*2-1/2 | 4.2*90 | #8*3-1/2 | 4.8*152 | #10*6-1/8 |

Packaging and Shipment

Our Market

Our Customers