Yellow Zinc Plated Hex Socket Insert Nut For Wood Furniture

what is hexagon socket Insert Nut?

Hexagon socket insert nut is a type of self-tapping screw sleeve, also called self-tapping tooth sleeve, which is a new type of screw nut fastener for inner and outer teeth to strengthen the strength of thread, and it can play an excellent fastening effect in a specific environment. There are tooth lines inside and outside the self-tapping screw sleeve, embedded in soft materials such as plastic, aluminum cast iron, copper, etc., which can form high-strength internal thread holes, and the self-tapping screw sleeve (self-tapping tooth sleeve) can also repair the broken internal thread.

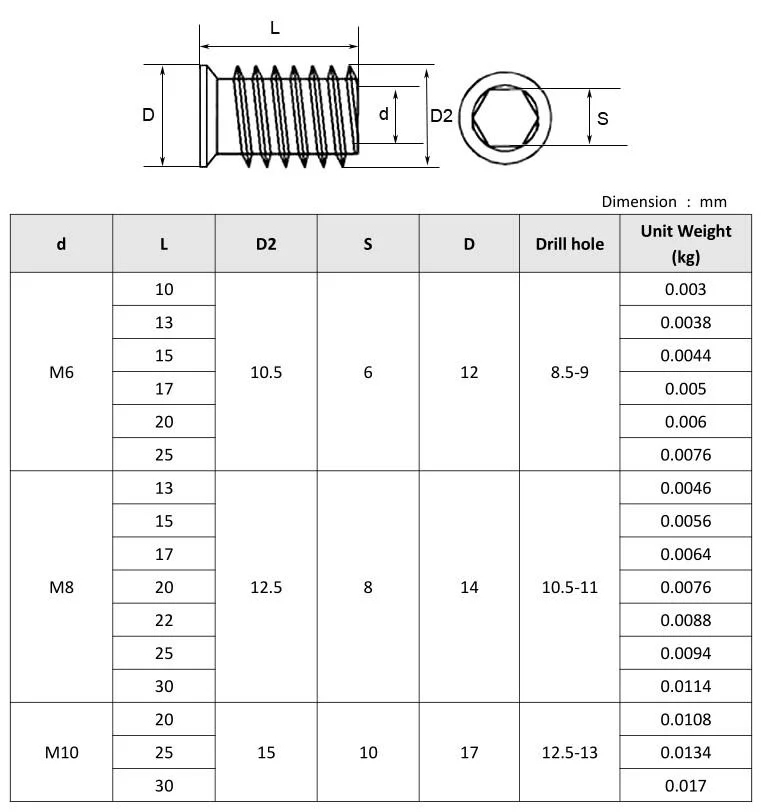

Size

product features

The installation of the self-tapping screw sleeve does not need to be threaded in advance, and it can be directly screwed into the specific hole reserved by the base metal by using the installation tool. For the thread of the mother who has broken teeth, it can also use the same screw as the original one, which is economical and beautiful, for new products, the thread strength can be increased.

Self-tapping screw sleeve (inner and outer tooth nuts) has been widely used in automobile industry, rail car industry, shipbuilding industry, household appliances, construction machinery, transaction machines, electronic products, engineering plastics, advanced composite furniture, aluminum die casting and other industries. The classification of self-tapping screws generally includes iron die, Wood tooth F is finger type, generally countersunk, A generally refers to type A tooth, that is, pointed tail tooth, B generally refers to type B tooth, that is, flat tail tooth.

Precautions for installation of inner and outer tooth nuts

▲ According to different processing materials, refer to the drilling size specifications for pre-drilling processing. When the hardness of the corresponding material is relatively high, please slightly enlarge the bottom hole within the drilling range.

▲ The slotted end of the screw sleeve is downward, and the self-tapping screw sleeve is completely installed into the front end of the tool, which requires vertical contact with the workpiece. When loading (1~2 pitch), please make sure to align with the bottom hole and never tilt. When the tilt is found, do not reverse the tool and re-adjust it before using it. After entering 1/3~1/2, you cannot come again. In addition, do not rotate the tool in reverse direction, otherwise it will cause product failure.

▲ The inner and outer tooth nuts should be at least 1mm lower than the surface of the parts after assembly.

Applications

Product Parameters

| Product name | Zinc Plated Steel Hex Socket Furniture Insert Nuts For Wood |

| Material Available | Stainless steel, carbon steel, alloy steel, brass |

| Surface treatment | Zinc plated, NI-platd, passivate, Chrome plated, Electro plating, Black, Plain, Sliver plated, Polish or according to your requirement |

| Packing | Plastic bag +carton box |

| Lead time | Sample 3-7 days, Mass production 8-15 days or according to customer's requirement |

Packaging and Shipment

Our Market

Our Customers